SpaceX is launching a mission about once every four days, and most of those flights are going to space to deploy Internet satellites for the company's own Starlink broadband network. But this week is different. Aside from two more missions carrying Starlink satellites, SpaceX is preparing to send a four-person crew to the International Space Station early Friday.

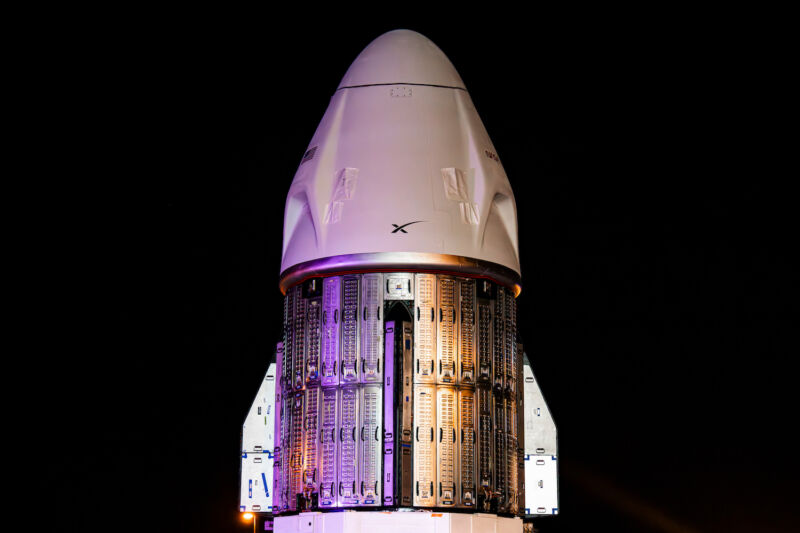

The crew launch from the Kennedy Space Center in Florida will deliver NASA commander Jasmin Moghbeli, European Space Agency astronaut Andreas Mogensen, Japanese astronaut Satoshi Furukawa, and Russian cosmonaut Konstantin Borisov to the space station for a half-year stay. This mission, known as Crew-7, will be SpaceX's 11th astronaut flight and the company's seventh operational crew rotation mission for NASA using a Crew Dragon spacecraft.

Bill Gerstenmaier, SpaceX's vice president of build and flight reliability, says these crew missions are special. SpaceX and NASA managers met Monday for a flight readiness review, a customary milestone before every crew launch, to deliberate on any problems that could affect the upcoming mission.

“It’s nice to get a chance to step back and look at all the issues, problems, and things that are going right with the vehicles," Gerstenmaier said. "We get a chance to take a look at the Falcon vehicle maybe in a little more in-depth way for crew flights than we do for other flights. We know the importance of flying crew, and the trust that the crew puts in us in delivering."

SpaceX has launched its Falcon 9 and Falcon Heavy rockets 81 times over the last year (that number could climb to 83 by the end of the week). Since the start of 2023, the company has launched its Falcon rockets 57 times, on pace for roughly 90 missions by the end of the year. For an orbital-class rocket, this is an unmatched launch rate in the entire history of spaceflight.

“We have separate teams that are monitoring all these activities," Gerstenmaier said. "In fact, we can support launches from three pads simultaneously with our support teams the way we are. So we’re not overstressed, we’re not overworking the workforce."

According to BryceTech, SpaceX launched more than 447 metric tons of payload mass in the first half of this year, nearly 10 times more than all Chinese rockets.

"From the outside, it may look like we’re flying a lot of flights, and they’re all trouble-free," Gerstenmaier said. "They are not all trouble-free. They are not easy. Every time we fly, we learn something. We spend the time to go analyze it."

Cleared for flight

NASA and SpaceX officials gave the green light Monday to proceed with preparations to launch the Crew-7 mission Friday, but only after formally signing off on several technical issues. One of those involved a drogue parachute that took longer than anticipated to fully inflate on a Dragon crew capsule returning from the space station earlier this year.

That issue was cleared for the launch of the Crew-7 mission during the flight readiness review.

“The parachute system is something that we monitor very carefully," said Steve Stich, manager of NASA's commercial crew program. "We have imagery of the chutes every landing, and SpaceX has done a great job of recovering those chutes from every single landing.”

Stich said the other "special topic" discussed Monday was a valve failure on a Dragon cargo capsule in June. During that mission, an isolation valve in the Dragon's propulsion system became stuck. There was no effect on the Dragon resupply mission because the valve in question is only used if there's a problem elsewhere in the propulsion system, when it would close or isolate a leaky thruster to avoid losing propellant.

SpaceX engineers removed the stuck valve from the Dragon cargo capsule after it splashed down at the end of its mission in June. They found signs of corrosion.

"The corrosion is caused by oxidizer vapors mixing with a little bit of moisture," Stich said. "The materials are corrosion resistant, but if you get enough vapor from the oxidizer along with water, you can form a little bit of acid and get some corrosion."

That may sound familiar for Ars readers. A test flight of Boeing's delay-stricken Starliner crew capsule, which still hasn't flown with astronauts, was grounded in 2021 after engineers discovered stuck valves in the spacecraft's propulsion system just hours before launch. Inspections revealed corrosion in the valves caused by moisture mixing with vapors of nitrogen tetroxide, the oxidizer used for maneuvering thrusters on both Starliner and Crew Dragon.

Stich said the process that led to the corrosion is "somewhat similar" to the issue facing the Starliner and Dragon spacecraft. "We have, on the valves, an environmental seal that leaks a little bit of vapor across into the dry side of the valve, which is the electrical part that actuates the valve, and then forms corrosion on the components inside, combined with a little bit of moisture," he said.

There were numerous stuck valves inside Boeing's Starliner spacecraft, delaying its unpiloted test flight by more than nine months. Over the last couple of months, SpaceX was able to remove valves on the Crew Dragon Endurance spacecraft slated to fly the Crew-7 mission, replace some parts in the valves, then reassemble them and test them on the capsule. "We know all of those valves are functioning just fine," Stich said.

"We’re very agile in the fact that we can get into tests (of hardware)," Gerstenmaier said. "We have a lot of vertical integration. We can do things ... to tear valves apart and dissect things. We use the NASA team where appropriate. We shift some of the work to them to go take a look. I think that’s a strength between us both to make sure we’re ready to fly.”

The valves on SpaceX's Crew Dragon Endeavour spacecraft currently docked at the space station are also functioning as designed. Ground teams will likely remove and inspect those valves after the capsule returns to Earth next month, following the launch of the Crew-7 mission.

"I would say we learned quite a bit from the investigation we did on Starliner, and it probably helped us get to the root cause a little bit faster on the Dragon valve issue," Stich said. "The materials inside the valves are a little different, so the kind of corrosion is a little different between the Dragon valve and the Starliner valves, but it’s a similar mechanism."

Stich said SpaceX and NASA would consider adding purge air to the propulsion system to keep vapors from building up and leading to corrosion. That's similar to something Boeing did to mitigate the problem with Starliner's corroded valves.

"I think we’re learning a little bit about capsules and valves between the two different vehicles—Starliner and Dragon—and we have a little bit more work ... to remediate the corrosion for the long term because we really want to re-fly each one of these (Dragon) vehicles up to five times," Stich said.

3175x175(CURRENT).thumb.jpg.b05acc060982b36f5891ba728e6d953c.jpg)

Recommended Comments

There are no comments to display.

Join the conversation

You can post now and register later. If you have an account, sign in now to post with your account.

Note: Your post will require moderator approval before it will be visible.