It can now try out new tires in a dynamic sim before making physical test tires.

Tires might be one of the more prosaic parts of a car, but they are undoubtedly among the most important. Bench racers might obsess about powertrain specs, and average consumers mostly want to know that there's wireless charging for their phones, but it's the tires that actually make contact with the road. Without them, no one is going anywhere. At least not very far.

In the past, tires have been considered somewhat mysterious, with secret blends of rubber, carbon, and other stuff combined with clever arrangements of belts and wires to hold the whole thing together as it rotates faster and faster without flying apart. These days, we know an awful lot about how tires work. Or at least tire companies like Goodyear do, having amassed enough testing data to be able to simulate them accurately enough to shave months off a development schedule.

In fact, the use of simulation in tire research and development has quite a long history. Chris Helsel, who is now Goodyear's CTO, joined the company back in 1996; he was hired as part of a tiny team doing computer tire simulation. "At Goodyear in '96, it felt like almost late to the party in terms of doing what we call finite element analysis, which is basically breaking a large structure down into little parts," Helsel said.

The complexity of the problem shouldn't be understated. "A tire deforms 40 percent every time it rotates, so that huge amount of displacement, or change, causes those elements to displace, and that causes numerical instability," Helsel explained.

Next, there's the contact between the tire and the road surface. "That concept of solving the friction equation at that interface—very challenging," Helsel said. And don't forget, you also have to simulate how the tire makes contact with the rim.

On top of that, the model also has to account for the tire rolling "and then, finally, the huge amount of detail when you look at a tread pattern and those little blades and things in it that are there for traction. How do you represent those in geometry?" Helsel said.

Back in the '90s, Goodyear was just trying to use that technology to predict things like contact patch shapes. Now, it's able to model tires in full fidelity, including in different climatic conditions. "Even snow, which is a really challenging problem because of the fracture mechanics aspect of snow," Helsel said. "Snow is connecting, then it's breaking apart. That's a really challenging numerical problem." A long-running partnership with Sandia National Laboratories has helped the process.

Driving on new tires before they exist in the real world

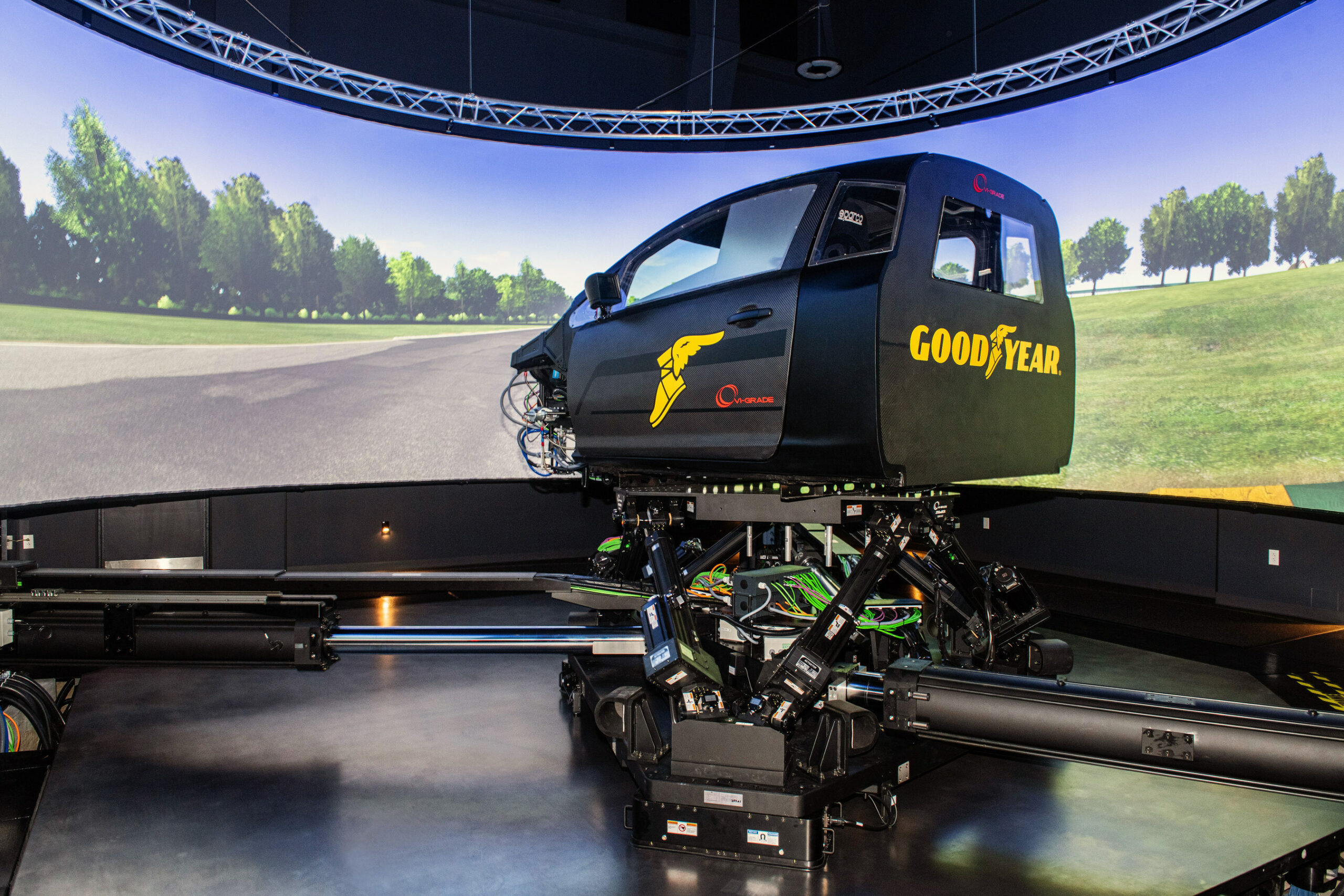

In silico tire development now extends much further into the tire testing process, as Goodyear is using driver-in-the-loop simulators—similar to the kind used in motorsport—to perform dynamic tire testing without anyone getting their hands dirty swapping wheels and tires on a test vehicle.

"When you take that tire model Chris described and the high fidelity of the vehicle model and put them into a driving simulator, the No. 1 problem is you want it to execute in real time. You want the human to feel like it is a real-world simulation," explained Steve Rohweder, VP of technology development at Goodyear.

"If it's a one-second maneuver, you want it to take one second, right? Those millions of degrees of freedom model do not necessarily execute in real time like that. So there's a translation that has to happen to be able to drive the simulator," Rohweder said.

Goodyear now has a pair of dynamic simulator centers, one in Akron, Ohio, which opened in 2021, and a second in Luxembourg, which opened in 2024.

The payoff is that it's now much faster to iterate during development. "Back in the late '90s, you could count on a half a dozen—maybe up to 10—physical iterations where you're actually ordering a mold, making tires, and putting them on test. [If] you didn't get the result, [you would] work your way back through," Helsel said.

Over time, simulating the tire's footprint allowed Goodyear to cut that in half, "and then since we've really been pushing this higher fidelity tire modeling and now into the simulator, we've cut that in half again," Helsel said. Now, when working with a car manufacturer on tires for a specific model, "we only need basically a build and test confirmation physical [tire], so [we're] down to one," Helsel said.

That's quite a savings—perhaps as many as 13,000 tires and 60,000 miles of test track driving that would otherwise be needed before everything was signed off.

"We've done variation in studies with [tire] sizes when we're setting targets working with the manufacturer before they start the vehicle development," said Rohweder. "Tire dimension is easy to adjust. Compound, major design changes—when you have the data and you prepare it, you can go into the simulator environment and quickly move around in the design space to find out what the driver feels is most effective and best for shooting on that target. So that's why we say that the maturity of that first physical iteration is really the benefit," Rohweder said.

Hope you enjoyed this news post.

Thank you for appreciating my time and effort posting news every day for many years.

News posts... 2023: 5,800+ | 2024: 5,700+

RIP Matrix | Farewell my friend ![]()

3175x175(CURRENT).thumb.jpg.b05acc060982b36f5891ba728e6d953c.jpg)

Recommended Comments

There are no comments to display.

Join the conversation

You can post now and register later. If you have an account, sign in now to post with your account.

Note: Your post will require moderator approval before it will be visible.