While silicon-based solar cells dominate the photovoltaics market, silicon is far from the only material that can effectively harvest electricity from sunlight. Thin-film solar cells using cadmium and telluride are common in utility-scale solar deployments, and in space, we use high-efficiency cells that rely on three distinct materials to harvest different parts of the spectrum.

Another class of materials, which we're currently not using, has been the subject of extensive research: perovskites. These materials are cheap and incredibly easy to process into a functional solar cell. The reason they're not used is that they tend to degrade when placed in sunlight, limiting their utility to a few years. That has drawn the attention of the research community, which has been experimenting with ways to keep them stable for longer.

In Thursday's edition of Science, a research team from Princeton described how they've structured a perovskite material to limit the main mechanism by which it decays, resulting in a solar cell with a lifetime similar to that of silicon. While the perovskite cell isn't as efficient as what is currently on the market, a similar structure might work to preserve related materials that have higher efficiencies.

Why perovskites?

Perovskites aren't a single material; instead, they're a large family of chemicals that adopt a similar configuration when crystallized. They can be formed from a variety of elements and even incorporate organic chemicals as one of the ions present in the crystal. This flexibility means that, despite the structural similarity, perovskite crystals can have distinct properties based on the chemicals that make up that structure.

These properties sometimes include a strong photovoltaic effect (if they didn't, this would be a very short article). The materials have a number of advantages compared to the ones we're using for solar cells. For starters, they can often be made from very cheap raw materials—lead is one of the more commonly used elements in photovoltaic perovskites, for example.

It's also relatively simple to get perovskites to form high-quality crystals when they precipitate from solution, making them much easier to work with. Solution processing is inexpensive and easy to scale, and it can potentially apply photovoltaic layers to a range of materials and surfaces.

So why is almost everyone still using silicon? To begin with, perovskites tend to be far less efficient at converting photons to electricity than the competition. That has been a significant factor in part because most of the expenses in solar installations come from permits and installation costs, which puts some premium on getting the most out of every panel you install.

Recent developments have identified perovskites that hold efficiencies similar to that of silicon—at least for a while. Unfortunately, the performance of most perovskites decays rapidly since the crystal structures they form tend to break down over time as they're exposed to light. Most perovskites we've tested would lose a significant percentage of their production within a year, and few have the stability to maintain high productivity beyond five years.

In it for the long haul

The problem is less that the perovskite structure is unstable and more that the atoms that get bumped out of the structure are able to diffuse away from it. If the atoms didn't have any place to go, the structure would be more likely to be stable over longer periods.

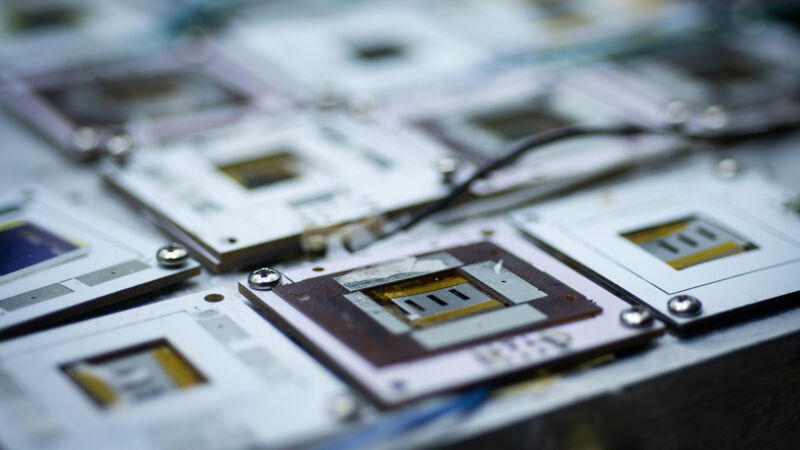

To fix this issue, the researchers sacrificed a bit of efficiency, choosing cesium lead iodide (CsPbI3) as their photovoltaic material. This material converts a bit over 17 percent of the incoming photons to charges (silicon materials typically have efficiencies of over 22 percent). But it has a significant advantage in that it's possible to make a cap for the material that is chemically very similar. Specifically, the team generated a cap composed of the related chemical Cs2PbI2Cl2 by exposing the perovskite to chlorine. So all of the atoms that could be bounced out of the perovskite and into the cap layer would find that the spaces they could occupy would already be filled by the same atom, which should slow the diffusion considerably.

To test how well this worked, the team made perovskite devices with and without the cap and exposed them to constant light at various temperatures. Without the cap, they could image the perovskite's decay in the uncapped material, and they linked that to the loss of iodine from the material. The cap appeared to largely prevent that loss.

Critically, the cap had to be thin enough to allow charges to filter through it and reach the layer that gathers them for use in generating a current. Keeping the cap to a 20-nanometer-thick layer seemed to be sufficient; in fact, the cap improved the efficiency of the perovskite material from under 15 percent to over 17 percent—still well below silicon but closer to being competitive.

What does this mean in practical terms? While it wasn't possible to run the panels out to 20 years to watch how their performance would decline, the team tracked shorter-term declines at different temperatures and used the data to generate a formula that extrapolated the panel's behavior into the future. The results were used to determine when the panels would hit the point where they produced just 80 percent of their original rated power, called the T80.

On its own, the capped material was measured as having a T80 of over 2,100 hours at 110° C, which is an unreasonably high temperature. Scale that number down to the more reasonable 35° C, and the extrapolation suggests over five years of continuous operation. Obviously, solar panels don't operate continuously, so you can at least double that time frame given the inevitability of cloudy and cooler days. According to Lynn Loo, who led the team, the durability of the material would be competitive with silicon in many areas of the US.

That's the durability—the efficiency is notably lower, meaning this system would still be uncompetitive at the per-panel level. That may not matter for some applications if the perovskite is much cheaper to make, though. And again, perovskites are a huge class of materials; it's entirely possible that we could use this approach to boost the stability of one with a higher efficiency.

Not that silicon is likely to be replaced; we've gone a long way toward optimizing its production, and its costs have gotten very low. But having additional options can give us flexibility when tailoring photovoltaics to different applications. If we're going to get the world running on renewable power, that sort of flexibility could be critical.

Science, 2022 DOI: 10.1126/science.abn5679 (About DOIs).

3175x175(CURRENT).thumb.jpg.b05acc060982b36f5891ba728e6d953c.jpg)

Recommended Comments

There are no comments to display.

Join the conversation

You can post now and register later. If you have an account, sign in now to post with your account.

Note: Your post will require moderator approval before it will be visible.