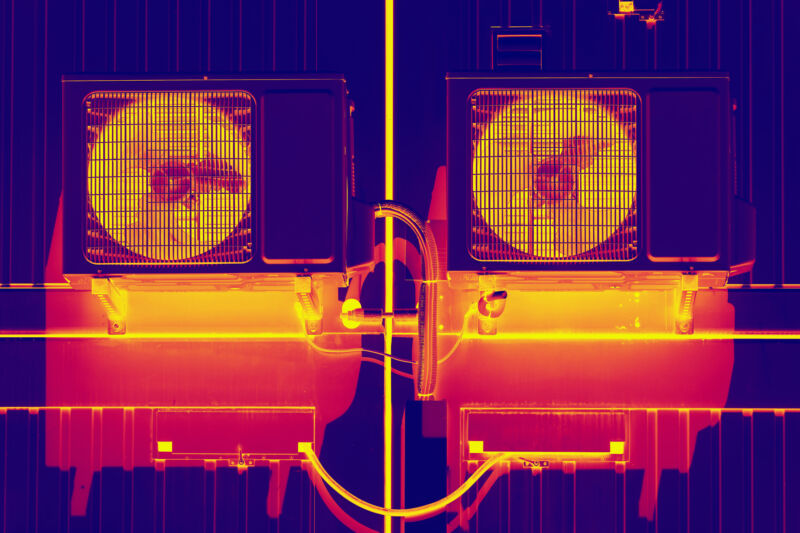

Various forms of heat pumps—refrigerators, air conditioners, heaters—are estimated to consume about 30 percent of the world's electricity. And that number is almost certain to rise, as heat pumps play a very large role in efforts to electrify heating to reduce the use of fossil fuels.

Most existing versions of these systems rely on the compression of a class of chemicals called hydrofluorocarbons, gasses that were chosen because they have a far smaller impact on the ozone layer than earlier refrigerants. Unfortunately, they are also extremely potent greenhouse gasses, with a short-term impact several thousand times that of carbon dioxide.

Alternate technologies have been tested, but all of them have at least one major drawback in comparison to gas compression. In a paper released in today's issue of Science, however, researchers describe progress on a form of heat pump that is built around a capacitor that changes temperature as it's charged and discharged. Because the energy spent while charging it can be used on discharge, the system has the potential to be highly efficient.

Pumping heat

Heat pumps are a great choice for heating since it's possible to move heat between a sink and a source using far less energy than it takes to simply heat the source up by, for example, burning natural gas. And, since the processes that are used for this work just as well in reverse, the same basic approach can be used for cooling.

It may sound counterintuitive that you could somehow extract heat from a room-temperature environment and export it into blazing hot desert air. But the process relies on creating a temperature difference between a working material (like those hydrofluorocarbons) and the environment. As long as the hydrofluorocarbons can be made hotter than the outside air, they can export heat to it. Similarly, they just have to get colder than whatever Arctic blast they're working against when being used for heating.

For hydrofluorocarbons, the difference in heat content can be controlled by altering the pressure. Compressing a gas will heat it up while lowering the pressure cools it down. However, various other materials undergo similar heating and cooling in response to other external influences, including physical stress, magnetic fields, or electric fields. In many cases, these materials remain solid despite experiencing significant changes in temperature, which could potentially simplify the supporting equipment needed for heating and cooling.

In the new work, done by researchers mostly based in Luxembourg, the researchers focused on materials that change temperature in response to electric fields, generically known as electrocalorics. While a variety of configurations have been tested for these materials, researchers have settled on a layered capacitor structure, with the electric field of the material changing as more charge is stored within it. As charge is stored, an electrocaloric material will heat up. When the charge is drained, they'll draw in heat from the environment.

This has a significant advantage regarding the power needed for the device to operate since the current generated when draining the capacitor can just be used to power something. There's a little energy lost during the round-trip in and out of storage, but that can potentially be limited to less than one percent.

The thing that uses power is the fact that the capacitors are entirely solid-state—on their own, they'll just sit in either the source or sink environment. So, you either have to expend energy to physically move the device between the environments or transfer heat from the electrocaloric device to some other material that does the moving. In this case, the researchers simply exchanged heat with the source and sink by pumping a liquid through the electrocaloric material.

3175x175(CURRENT).thumb.jpg.b05acc060982b36f5891ba728e6d953c.jpg)

Recommended Comments

There are no comments to display.

Join the conversation

You can post now and register later. If you have an account, sign in now to post with your account.

Note: Your post will require moderator approval before it will be visible.